PTC inks – Controlling temperature in electronic devices

Avoid hot spots in your printed circuits

A Positive Temperature Coefficient (PTC) heating element has a certain resistance. With PTC inks, the resistance increases together with the temperature. When a voltage is applied a current will flow and power is generated. The heater heats up and the resistance increases. At a certain temperature, an equilibrium is reached, that’s a self-regulating heater!

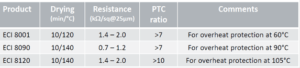

These products are carbon based PTC inks with different “switch off” temperatures for low voltage (<50 Volt) applications. They can be applied by screen printing and are compatible with polyester foil, several silver inks, dielectric inks and spacer tapes.

Increased Safety

With PTC* Inks, no risks of overheating! Select the ink according to your target temperature and print the heating elements of any electronic applications.

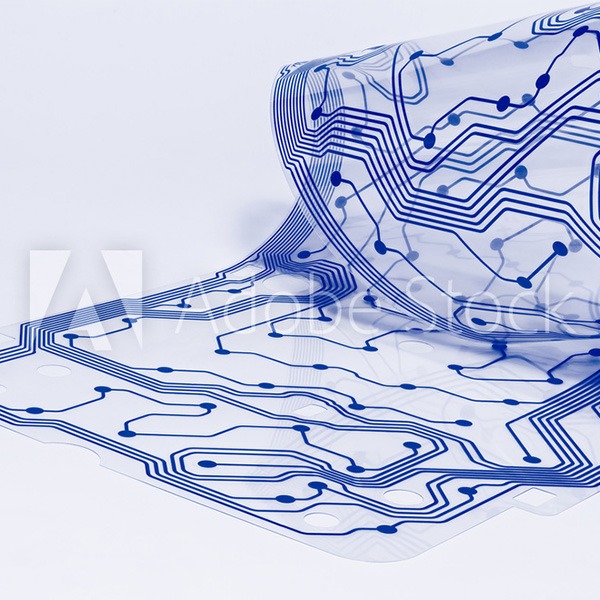

Adaptable design

Design is very important and requires information like heater dimensions, temperature needed, substrate, voltage used and required power. With light and thin layers, the design of your circuit can be easily adjusted to the shape of the surface that needs to be heated.

Cost-effective and sustainable

Compared to etch processes, PTC inks uses a screen-printing process allowing for reduced waste of material. A great cost/benefit option!

PTC heaters requires the use of silver inks to print busbars and contact areas. Reduced resistance of silver ink will improve the current capacity of the busbar. Loctite ECI1010 is the most recommended silver ink for PTC heater. It combines excellent conductivity with optimum mechanical strength.

A new product development is currently on-going targeting high voltage PTC heaters (up to 250 V) with higher resistance level and a temperature of 60°C. If interested by this type of products, let us know.

The Tetrachim team is at your service to select the right inks for your application.